According to the Wikipedia Homogenization is any of several processes used to make a mixture of two mutually non-soluble liquids the same throughout. This is achieved by turning one of the liquids into a state consisting of extremely small particles distributed uniformly throughout the other liquid. A typical example is the homogenization of milk, wherein the milk fat globules are reduced in size and dispersed uniformly through the rest of the milk.[1]

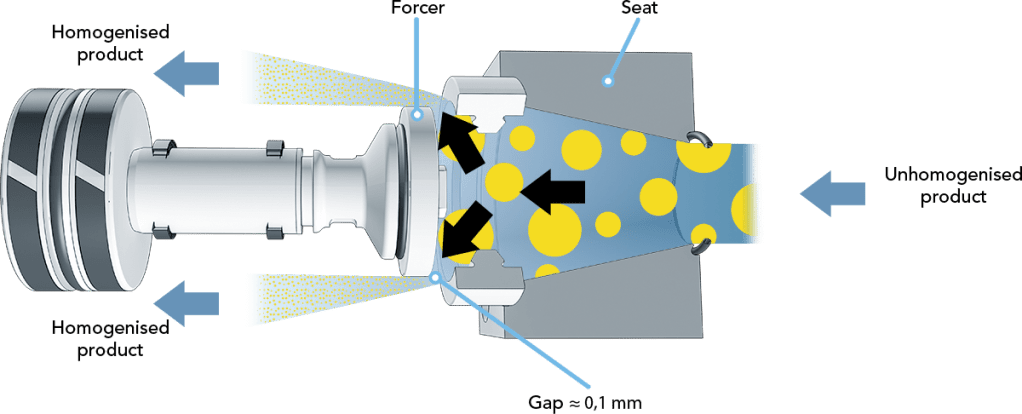

Picture1

As its Clear in the Picture 1, The Big micro particles in two or different In immiscible liquids as homogenized products enters the nozzle under high pressure ranging from 100 to 1500 Bar and due to the pressure The Liquids turn into emulsion with small micro particles. The liquid would pass the small designed passage and The outlet would be homogenized Liquid. The benefit of a homogenized Liquid would be higher stability and lifetime on the shelves in The market and diffusing the concentration of micro particles in an emulsion form.

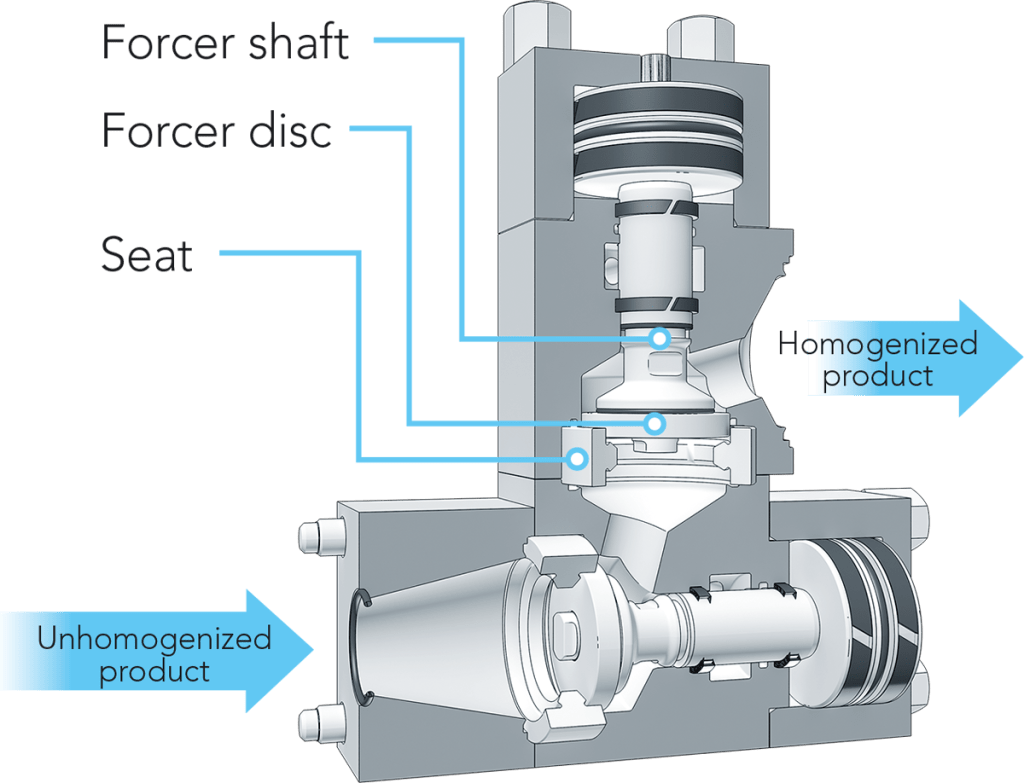

Picture 2

As it shows in The Picture 2 The Mechanical Part of the Homogenization process includes Seat, Force disc & Force Shaft. The Force disc is usually getting under pressure by a pneumatic of hydraulic force applied on the Shaft. The mechanical part of the valve needs to be manufactured from high tolerance and high quality material to be able to function properly under intense condition. Due to the Cavity and turbulence created by high back pressure of the liquid and small (0.1 mm) passage of the flow, constant maintenance is needed.

TOP two Homogenizer Machine in the Market

TSH Machinenbau GMBH

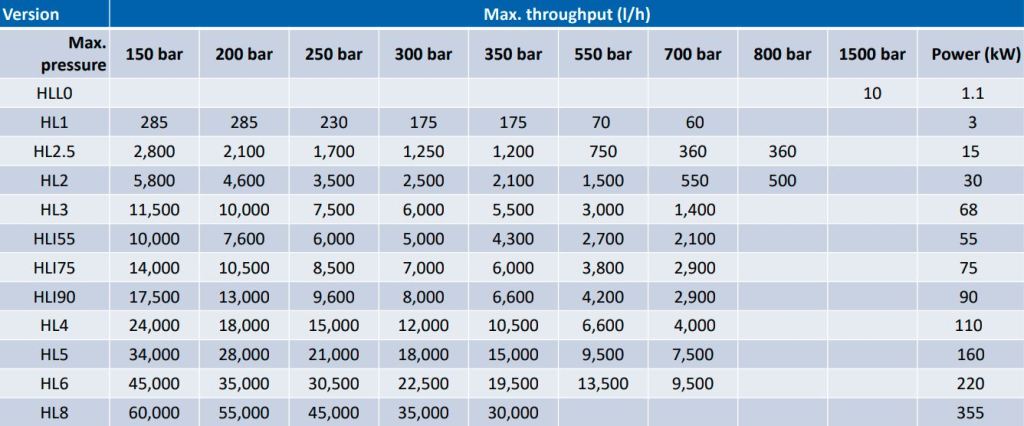

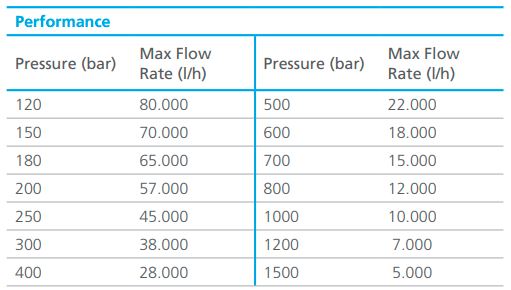

This German Company Located at Dassow city is a purchased by Krones Group. They specifically manufacture Homogenizer and Piston Pump. their homogenizer can process up to 10 to 60000 L/H at a pressure of 100 to 1500 bar. Below at picture 3 you can find the performance overview Table:

There are two type of Valve in HST homogenizer Machines:

1- Puppet Valve:

- high volumetric efficiency with low viscosity products

- Max product Viscosity up to 500 mPas

- Permit High speed > 160 min-1

- Suitable for smooth and slightly abrasive Material

2- Ball Valve:

- Bigger Particle Tolerance

- Product viscosity up to 1,000,000 mPas

- Limited speed up to 160 min-1

PROS VS CONS:

Pros:

- Valve design technology is based on Hydraulic or Pneumatic performance

- Internal Lubrication, No cooling water, No auxiliary Unit

- Valve adjustment and fluid turbulence damping structure

- sound reduction cabinet

- Higher energy efficiency

Cons:

- The Output flow rate comparing to the competitors is lower

- There are not so much document and videos about the machine

- The pressure is lower Comparing to the competitors

GEA Ariete Homogenizer 5200

GEA is an International Company, which its headquarter is located in Italy.

The Ariete series is the state-of-the-art technology for powerful reliable high pressure machines and customized solutions. The Ariete machines, compliant to EU safety

rules (CE standards) and built according to EN ISO 9001:2008 Quality System, are the best fit for pharmaceutical, dairy, food & beverage, biotechnology, chemical and cosmetics industries.

GEA Ariete machine can up to 80,000 L/H at the pressure of 120 bar produce homogenized emulsion.

Leave a comment