1- Siemens:

Siemens is the most well know and famous producer of Industrial Controllers in the market. The two main production line that i would like to talk about them are S7-1500 and S7-1200:

S7-1500:

Using the SIMATIC S7-1500 controller gives you top performance and built-in viability into the future. You can turn the most sophisticated machine designs into reality thanks to the modular structure of the controller, which provides reliable assistance as you work your way through the digital transformation.

The main feature of the S7-1500:

- The Multifunctional Platform TM MFP is designed for integrating various independent applications.

- Openess for customized high-level language applications., e.g. C/C++ for

– protocol converters,

– database connection,

– complex algorithms,

– integration of vision systems. - Possible use of optional software packages and edge apps e.g.Proneta or SIMATIC Flow Creator.

- The S7-1500 TM NPU module operates using a trained neural system.

- The module can be seamlessly integrated into the SIMATIC automation system permitting a simple and profitable combination of AI algorithms and PLC logic. This is how inexpensive and rescalable applications using SIMATIC can be implemented at the machine based on artificial intelligence, e.g

- Smart object recognition of any workpieces

- Visual quality check of products

- Quality checking using sensor and production data

- Multifunctional platform for PC- and control tasks

- Due to its connectivity and high computing power the MFP CPU is suited for sophisticated control tasks as well as for PC-typical applications that require high-level language programming, are developed model-based or must be implemented using databases

- Every SIMATIC S7-1500 CPU supports motion control functions.

S7-1200:

SIMATIC S7-1200 controllers by Siemens are the intelligent choice for compact automation solutions with extended communication options and integrated technology functions. They are available in standard and failsafe versions.

The main feature of the S7-1200:

- New webserver

- OPC UA enhancement by methods and integrated diagnostics

- Compact read/write ASCII-files

- GetSMCInfo: Which provides info of the memory stick

- Timestamp format

- MRP master functionality for CPU 1215/1217

- Configured OUC connections

- More retentive memory

- S7-1200 Motion Control axis control panel

(Jogging and velocity specification during non-position-controlled operation) - The central processing units of the SIMATIC S7-1200 PLC are designed as Compact CPUs with integrated I/Os. Their modular design can be used to increase the configuration limits or to adapt the controller to new tasks: through mounting a Signal Board on the CPU or adding separate signal modules.

- Special modules enhance the application area of the whole system, e.g. for Codition Monitoring, integrated weighing technology, simulation of input signal or for extending the power reserve for the S7-1200 real-time clock by an additional battery board.

- Communication modules increase the communication capabilities of the SIMATIC S7-1200 PLC through additional functions and interfaces. S7-1200 communication modules support serial communication, PROFIBUS, IO-Link, AS-Interface and several mobile standards.

Tia Portal as Software:

- The cloud-based engineering solution for Totally Integrated Automation (TIA)

- Mobile working that includes remote access to important tools and projects is more relevant than ever before. With TIA Portal Cloud, you can continue to perform your engineering tasks quickly, efficiently, and securely – only now you can do so from anywhere and at any time. Thanks to the cloud services, you have access to the right TIA Portal version, without installation or updates. To save time, you can also save your projects in the cloud and can just as easily share them with colleagues – naturally, in line with the strictest cybersecurity standards.

- Improve software quality and reduce engineering costs in automation

- In the IT sector, there are many methods and processes for optimizing software development while also improving the quality of the results. One such process is Continuous Integration, which can also be applied to engineering in automation projects with TIA Portal and offers numerous benefits.

- Rely on an integrated engineering workflow with libraries in the TIA Portal

- Running work processes in parallel using integrated digitalization promises huge time gains in the development of new machines. Standardization provides the basis: You get a handle on the increasing complexity of applications, you can respond quickly to constantly changing customer demands, and you can guarantee consistent top quality in the development process. The Totally Integrated Automation Portal (TIA Portal) checks all the boxes.

- Your shortcut to robotics

- The SIMATIC Robot Integrator app lets you integrate robots from different manufacturers into your machine structures quickly and easily via TIA Portal, with no assistance from external specialists. Now with the universal SIMATIC Robot Library, TIA speaks the same language as the robots. The app offers machine builders and end customers new opportunities for flexibility and efficiency.

- The SIMATIC Robot Integrator now makes the benefits of robotics readily available to all users. To integrate robots, you just need to know your way around the TIA Portal. That saves on engineering costs: Users benefit from a single engineering environment for machines and robots and from the uniform operation of robots from different manufacturers.

The app makes integration even faster and easier with the universal SIMATIC Robot Library, which enables TIA Portal to speak the same language as the robots.

PROFIBUS and PROFINET International (PI) has adopted the Standard Robot Command Interface (SRCI) that’s integrated in this library as the new standard for uniform communication with robots. The library is also certified by PLCopen, which highlights the relevance of the app as an element in plant standardization strategies. - Access to rapid testing of PLC modules

With SIMATIC S7-PLCSIM Advanced integrated as an option into TIA Portal - Easy plant modeling using time sequences and switching

With SIMATIC S7-PLCSIM Advanced and model creation using SIMATIC STEP 7 - Complex models created in high-level languages

By connecting to independently created applications (C, C#, third-party, etc.) using the PLCSIM Advanced interface - Simulation of automation in the context of a machine or plant

By connecting PLCSIM Advanced to SIMIT, NX MCD, Process Simulate or Plant Simulation

2- Rockwell Automation -Allen Bradley

Allen Bradley takes the second place in the list. From the original programmable logic controller (PLC) invented in the 1970s to the scalable, multi-disciplined and information-enabled programmable automation controller (PAC), Allen‑Bradley® control systems help you meet complex to simple application requirements. With multi-disciplined control solutions built focusing on controllers and I/O and combined with attachment portfolios, you can deliver a smart, productive and secure Integrated Architecture® system in discrete, process, motion, and safety applications. We have got you covered. A modern control system is more than its name implies. It delivers the fast system performance, high capacity and optimized productivity that you need from a control system today. We will compare the two PLC sereis of 5580, 5380 and 5069 plus the Software as below:

ControlLogix® and GuardLogix® 5580:

- 5580 family of controllers use the Studio 5000® design environment as the standard framework that optimizes productivity, reducing time to commission. This framework manages Integrated Motion over EtherNet/IP for high-speed motion applications and SIL2/PLd and SIL3/PLe safety solutions.

- ControlLogix 5580 controllers provide multi-discipline control for discrete, motion, process and safety applications.

- Logix offerings work together in what its call Integrated Architecture® offering. It helps you keep costs down and reduce system complexity.

- The ControlLogix 5580 controller incorporates security mechanisms like centralized authentication and access control to help keep your systems secure.

- Offers certification to a robust control system security standard – TÜV Rheinland IEC 62443-4-2

- Gains up to 45% capacity when using the 5580 controller

- Includes a 1 gigabit (Gb) embedded Ethernet port that enables high-speed communications, I/O, and motion control

- Offers controller functions that maximize system performance

- Includes controller-based change detection and logging, digitally-signed controller firmware, and role-based access control for extra security

- Provides a display that allows for enhanced diagnostics and troubleshooting

- Offers conformal coating to help protect in harsh environments; these products include a “K” in the catalog number

- Offers memory options from 3 MB to 40 MB

- Includes a 1756 Slim Power Supply option for series B and C standard and 1756 XT Chassis, which offers a 29% reduction in width when space is limited

- Offers chassis with up to 17 slots in standard and conformal coated

CompactLogix™ and Compact GuardLogix® 5380:

5380 controllers provide higher performance, increased capacity, improved productivity and enhanced security to help meet the growing demands of smart machines and equipment for manufacturing. All standard and safety controllers use a modern programming environment, Studio 5000 Logix Designer® application, to allow users to work collaboratively to design and maintain their systems. This common environment optimizes efficiency, reduces time to commission and manages integrated motion over EtherNet/IP™ for high-speed motion applications and up to SIL 3/PLe safety solutions. These controllers are ideal for applications requiring high-performance communications, I/O and motion control for up to 32 axes.

Some features of 5380 family:

- Ideal for small to large applications that require low axis motion and I/O point counts

- Enable high-speed I/O, motion control, Device Level Ring and Linear topologies

- Offer a 1 gigabit (Gb) embedded EtherNet/IP port that enables CIP safety connections, I/O and safety devices

- Include dual configurable ports that support Dual-IP address

- Provide enhanced diagnostics and troubleshooting with controller status and fault display

- Offer controller functions optimized for maximum system performance

- Offer enhanced security features that include controller-based change detection, logging, encrypted firmware and role-based access control to routines and Add-On Instructions

- Support up to 31 local Compact 5000™ I/O modules

- Offer integrated motion on EtherNet/IP up to 32 axes

- Offer a wide range of memory options from 0.6…10 MB

5069 CompactLogix™ 5480 controllers:

These controllers are real-time controllers with Windows 10 IoT Enterprise running in parallel to the Logix control engine. CompactLogix 5480 uses the same re-architected control engine deployed in the ControlLogix® 5580 and CompactLogix 5380 controllers. This line of Logix controllers supports embedded Windows applications, such as analytics, data gathering, and predictive computations. The ability to collect data and make decisions at the machine level helps to support the Connected Enterprise and benefits both end users and OEMs.

- Provides a Logix based real-time controller that runs an instance of Windows 10 IoT Enterprise

- Supported in Studio 5000 Logix Designer® version 32

- Is ideal for mid-size to large applications requiring high performance control and data throughput

- Enables high-speed I/O, motion control, and Device Level Ring/Linear topologies

- Includes three GbE Ethernet/IP ports that enable high-speed communications, I/O, and motion control (two are configurable, and support Dual IP address or Device Level Ring)

- Includes one GbE Ethernet port as a dedicated commercial OS network interface

- Supports up to 31 local Bulletin 5069 Compact I/O™ modules

- Offers enhanced security features that include digitally-signed controller firmware, controller-based change detection, and a log of role-based access control to routines and Add-On instructions

- Allows users to deploy Windows 10 based off the shelf and/or custom applications while tightly integrated with real time Logix control

- Includes integrated DisplayPort for high definition industrial monitor connectivity

- Includes two USB 3.0 ports for OS peripheral and expanded data storage capability

Rockwell automation- Allen Bradley- The software:

- The Studio 5000® environment combines elements of design into one standard framework that optimizes productivity and reduces time to commission. This intuitive integrated design environment focuses on rapid design, re-use, collaboration and virtual design. The updated user interface provides a common, modern user experience across all Studio 5000 applications.

- With the ControlLogix® 5580 family of controllers, you can configure your controllers and develop all elements of your control system in one place — the Studio 5000 design environment. It is the marriage of the hardware and software that brings additional capabilities, streamlined processes, and productivity savings to life. For example, when these controllers are paired with the Studio 5000 Logix Designer version 33 application, the redundant capability, which is a function of firmware, is enabled.

Pros:

- It supports multiple Allen Bradley PLCs programming.

- Studio 5000 is the top program for any ladder logic needs

- Constant Updating

- Easy reusable blocks such as AOI and communicating with other devices

- Extensive help and tutorial options

- User friendliness

Cons:

- It does not have a free version available, at least to view the logic of PLCs for troubleshooting in the process.

- Expensive- full version 12 Month with subscription with Warranty cost 6300 Euro

- Only Online Help correction for errors in code

- Tag alias systems are annoying

- Lags and crashes a lot when opening IO config windows, especially online

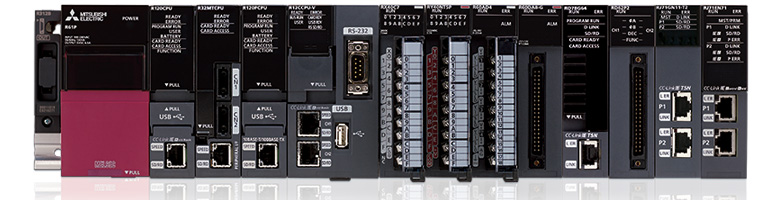

3- Mitsubishi Electric -Melsec

- MELSEC iQ-R Series: As the core for next-generation automation environment, Mitsubishi has realized an automation controller with added value while reducing TCO. The MELSEC iQ-R Series has been developed from the ground up to solve common problems in seven key areas: productivity, engineering, maintenance, quality, connectivity, security and compatibility. Taking a three-point approach to solving these problems: reducing TCO, increasing reliability and reuse of existing assets.

- CPU Programmable automation controllers suitable for various different applications.

- Base unit The base units are needed for installing devices such as power supply, CPU and I/O modules. Various types are available to suit multiple system requirements.

- Power supply This module is used for providing electrical power to CPU, I/O modules and other modules on the base unit.

- I/O module Devices such as switches, indicator lamps, and sensors can be easily connected to the control system using the digital I/O modules.

- Analog I/O module Analog modules are the main interface between the control process and the automation system and are specifically designed to interface with sensors that process varying voltage and current signals.

- Motion, Positioning, High-speed counter module Distinct set of high-accuracy and fast and intelligent control response modules that are ideal for applications requiring high-speed and precision.

Information/network module This module group enables information exchange with multiple control systems. The module lineup improves production efficiency

- The Mitsubishi MELSEC-F Series has been reborn as the MELSEC iQ-F Series, offering enhanced high speed bus, expanded built-in functions, advanced SSCNETIII/H support and improved engineering environment. Program and parameters are set with the GXWorks3 engineering software. From stand alone use to networked system application, MELSEC iQ-F brings your business to the next level of industry.

- CPU module All-in-one main unit with power supply, CPU and I/O. Built-in features include high-speed counters, positioning outputs, Ethernet, and SD card slot.

- I/O module I / O modules are available with and without built-in power supply, and in various input / output configurations.

- Analog Control module Options for analog inputs and outputs, temperature sensor inputs, and temperature control. FX3 series analog intelligent function modules can also be connected.

- High-Speed Counting module High speed counter modules. FX3 series high speed counter modules can also be connected.

- Simple motion / Positioning Control module Simple motion module supporting CC-Link IE TSN and SSCNETⅢ/H. FX series pulse output modules can also be connected.

- Network / Communication module RS-232, RS-485, RS-422 communication modules. FX3 series CC-Link master modules can also be connected.

- Safety extension module Safety extension module. Easily create a system just by connecting a safety extension module to FX5U/FX5UC CPU module.

- MELSEC-Q Series: its powerful performance takes the Q Series to levels rarely seen by other PLCs before. As the requirements of manufacturing evolve daily, the next generation MELSEC-Q Series, with its nano speed processing, can dramatically improve system and machine performance.

CPU A PLC CPU lineup that can fit any application.- Base unit These modules are for mounting devices such as power supply modules, CPU modules and input/output modules. A lineup of base units is available to suit your system needs.

- Power supply These modules supply electrical power for use by the CPU, input/output modules etc.

- I/O module These modules are for connecting input and output devices. Assorted I/O modules are available to suit your system needs.

- Analog I/O module These modules use an analog method for data input/output. They support process control needs and are perfect for high-speed, high-accuracy control.

- Pulse I/O module, counter module This pulse input, high-speed counter unit supports high-resolution devices and can offer high-accuracy control.

- Positioning module Modules for high-speed, high-accuracy positioning control. A variety of positioning modules are available to cater to different customer needs.

- Information module These modules enable information exchange with the host control system, enhancing production efficiency by collecting and controlling various production information.

- Control network module These interface modules provide connectivity to various networks that are found at each FA level of a factory automation system.

- Energy measurement module These energy measurement modules support measuring and monitoring of diverse energy information.

- The MELSEC-L Series: will innovate and evolve your production site by providing flexibility and excellent ease-of-use. The MELSEC-L Series has been designed based on a passion for monozukuri (creation), trustworthy technology and reliability. This concept also applies to system installation and operation.

CPU The L Series CPUs feature a variety of control functions and built in I/O included as standard. By adding additional modules it can be customized to suit each individual application.- Branch/extension module This module allows the system to be extended to match the size of your production facility.

- Power supply These modules supply electrical power for use by the CPU, input/output modules etc.

- I/O module These modules are for connecting input and output devices. Assorted I/O modules are available to suit your system needs.

- Analog I/O module These modules use an analog method for data input/output. They achieve fine tuned control with high-speed, high-accuracy and high-resolution.

- Counter module Easily and accurately count high-speed pulse with this module

- Simple motion module A variety of control methods including positioning control, speed control, torque control, cam control and synchronous control can be implemented easily.

- Positioning module These modules are for high-speed, high-accuracy positioning control

- Information module These modules enable information exchange with the host control system, enhancing production efficiency by collecting and controlling various production information.

- Control network module These interface modules provide connectivity to various networks that are found at each FA level of a factory automation system.

The PLC engineering environment has undergone outstanding innovation and growth culminating in the era of the new generation of MELSEC Engineering software! MELSEC’s many different software products provide solutions for TCO reduction across the engineering environment, for example, by improving design efficiency, shortening debugging time, reducing downtime and data holding.

iQ Works4 This comprehensive software suite includes programming software for efficient cross system engineering encompassing, for example, PLC, motion control and GOT.

GX Works This PLC sequence programming software uses the program assets cultivated by GX Developer to pursue a more comfortable level of operability.

PX Developer This software enables the easy creation of loop control programs with simple drag & drop operations.

MX Component This Active X controller library supports users to easily implement communication from the PC to PLC without the need for protocol knowledge.

MX Sheet This software enables Microsoft’s Excel package to monitor, log, collect alarm information and change configurations for the PLC.

Other engineering softwares Lineup of various software to support the MELSEC Series engineering environment.

Peripheral equipment support tools A lineup of software tools that further simplify developments made with MELSEC programmable controllers.

Pros:

- Integrated features in one platform including, programming, HMI design, Motion & servo design and communication set up

- Graphical and intuitive operability, easy programing by just “selecting”, and diagnosis function for easy troubleshooting reduces engineering cost.

- The GOT (Graphic Operation Terminal) screen creation software has been designed with 3 main features; Simplicity, Graphic Design, and Easy-Usability, further helping to create graphic screens with fewer steps.

- The motion control design and maintenance software includes intuitive graphic based programming together with a digital oscilloscope simulator.

- Supports various steps from programming, to commissioning, evaluation, and maintenance. In addition, improved preventative maintenance is realized through the use of an integrated 3D robot simulator.

- This software simplifies the setup and maintenance of AC Inverters. Parameters can be registered easily and distributed to multiple inverters when replacing, and activation of the PLC function all from one setup screen.

- It is the software for which the assets such as project and library are managed by the purpose. The revisions of registered assets are accumulated and it is easy to get the past assets. The purpose assets can be found quickly by filtering

- A Field Device managing/setting software which is MITSUBISHI ELECTRIC products and it is corresponding to FDT/DTM open specification.

And it can be used as a FDT frame application to set the parameters of Field Device, or to maintain/adjust the device.

Cons:

- It costs 500 Euro

- Not so user friendly like Allen bradley (Control logix) and siemens (Tia protal)

4. Schneider Electric_ Modicon

Modicon IIoT-native edge controllers manage complex interfaces across assets and devices or directly into the cloud, with embedded safety and cybersecurity. Modicon provides performance and scalability for a wide range of industrial applications up to high-performance multi-axis machines and high-available redundant processes.

The Modicon Family of PLCs stands for innovation, offering a full range of solutions to meet your automation needs. From small automated machines to advanced machine automation, our robust offer of trusted automation solutions enhances machines and processes across industries.

Modicon M251 logic controller:

The Modicon M251 with CANopen, Modbus TCP and EtherNet/IP let you easily connect to SCADA, MES, ERP by standard Ethernet cables and even via Wi-Fi. Boost your machine’s performance with data transfer via SD Card, embedded web server and more. Get unlimited access to your machine via Ethernet – everywhere and any time and simplify maintenance with any mobile device through visualization pages designed directly inside EcoStruxure Machine Expert and stored in the PLC’s web server.

- Expansion bus Modicon TM3

- Ultra compact format

- Up to 14 fast expansion modules

Boost the performance of your machine with powerful data transfer via SD Card, embedded Web- & FTP Server and more: - Program Download

- Firmware Update

- 22µs by instruction

- 64MB Ram and 128MB Flash

Integration & maintenance has never been easier – you are connected everywhere via - Serial line and USB port

- CANopen, Modbus TCP, and EtherNet/IP

- Embedded Ethernet switch with 2 ports

- Up to 3 communication modules

Modicon M262 logic controller:

- Modicon M262 logic and motion controller is:

• IIoT-ready to digitize your machine and giving a key position in Industry 4.0 architectures.

• Connected to devices, machines, and the plant with encrypted communication.

• A performing logic controller up to 7 times faster than Modicon M241 or M251.A motion controller as fast as 1 ms for synchronization and up to 24 synchronized axes, using g-code and able to drive robots with up to 3 axes. Very well adapted to simple and medium complexity motion applications such as drilling, milling, printing, and camming or packaging machines.

• Scalable and using the same I/O systems as M241, M251, or PacDrive.

• Having embedded safety, allowing up to SIL 3 thanks to the Safety Logic Controller (SLC). Safety I/O can be managed through the Sercos network. - Modicon M262 range includes several controllers providing choice in:

• CPU performance: 5 or 3 ns/inst

• Maximum number of synchronized axes for motion-centric applications: 4 (1ms), 8 (2ms) or 24 (4ms) synchronized axes (TM262M) - Features:

- The Modicon M262 is ultra-connected while protected by end-to-end cybersecurity and encrypted communication:

• Machine to devices: Thanks to open protocols such as OPC UA client/server, EtherNet/IP, Modbus TCP, Sercos.

• Machine to human: With improved diagnostics, Machine Assistant, and integrated WebVisu, saving time on commissioning and maintenance.

• Machine to plant: With a large choice of protocols and services, the Modicon M262 can be easily connected to ERP, MES, SCADA, CMS, CMMS…

• Direct machine to cloud: Push your data to cloud-based solutions such as EcoStruxure Machine Advisor. Boost controller and digital machine capabilities through the many existing cloud applications using API.

Modicon M221 logic controller:

- Everything you need is embedded:

- SD card and USB port

- 2 analog inputs and a broad choice of I/Os

- Run/stop switch and cartridge extension

- Ethernet and serial line ports

- High degree of flexibility lets you add additional modules easily:

- Safety module

- Extensive line of analog and digital modules

- Lexium servo drives

- Intuitive machine programming with EcoStruxure Machine Expert – Basic software

- Simple navigation delivers a more efficient engineering process

- All programming, visualization, and commissioning are handled in just one intuitive tool

- Available as a free download

- No training required

Modicon M241 logic controller:

The Modicon M241 logic controller offers best-in-class communication with 5 embedded ports. It offers you state of the art technical features and embedded CANopen for fieldbus architectures up to 63 devices while reducing your installation time and cost. Get unlimited access to your machine via Ethernet – everywhere and any time and simplify maintenance with any mobile

Everything you need is embedded:

- 5 ports: Ethernet, CANopen, 2 serial lines, USB port for programming

- High processing CPU and cartridge extensions

- Web and FTP server

- Pulse train outputs / high-speed counters

- SD card

Fast and easy configuration - Safety function

- Tesys SoLink motor starter

- Extensive line of analog and digital modules

- Ethernet and Profibus

Intuitive machine programming with EcoStruxure Machine Expert – the unique software for EcoStruxure Machine controllers - The right environment for every aspect of your machine: Standard and safe logic, motion design and HMI configuration.

- Build your application intuitively as never before due to an organised screen design

- Save engineering time by applying complete libraries or even a new machine module thanks to many predefined templates

- Download your software project on all devices with just one click.

- So Machine is one of the most modern and powerful tool-based software concepts on the market!

The software:

EcoStruxure Machine Expert is one of the most modern and powerful tool-based software concepts on the market!

The Modicon M251 logic controller is a EcoStruxure Machine controller. EcoStruxure Machine™ from Schneider Electric is an intuitive solution for machine automation with all the features and functions you need to build machines that will improve your bottom line. From design and development, to commissioning and maintenance, EcoStruxure Machine is a complete machine building solution with benefits all through the machine life cycle.

5-Omron -sysmac

Sysmac is an integrated automation platform dedicated to providing complete control and management of your automation plant. At the core of this platform, the Machine Controller series offers synchronous control of all machine devices and advanced functionality such as motion, robotics and database connectivity. This multidisciplinary concept allows you to simplify solution architecture, reduce programming and optimize productivity.

- Complete integration of motion and logic sequence

- Environment software for Configuration, Programming, Simulation and Monitoring

- The Sysmac platform is scalable and provides the performance and functionality for a wide range of solutions from simple machines through to manufacturing cells

- Motion Control: Integrated within the IDE, and operating in real-time

• Standard PLCopen Function Blocks plus Omron generated motion FB’s

• Direct Synchronous control for Position, Speed and Torque - The simplest way to integrate safety improves productivity and safety

• The PLCopen® safety FB’s simplify and accelerate the development process - • Higher resolution images available without increasing the vision processing time

• Shape search technology: Provides more stable and accurate object detection for Pick & Place projects - • One controller integrates two different types of engines, one based on cyclic scanning (PLC feature) and another based on procedural programming (robot feature), providing direct control of robots

- Full control of the process parameter setting and predictive maintenance functions

• High precision detection and positioning data synchronized on the network

some Features highlights:

• Sysmac communicates in real-time with Databases such as SQL

• Secure Data: In the event of a server going down or losing communications, data is automatically stored in internal memory

• Sysmac operates with Databases at high speed [1000 table element/ 100 ms] ensuring realistic Big Data Processing to improve productivity and aid predictive maintenance etc.

One Connection

Seamless machine control and factory automation

One machine control through one connection and one software is how we define the Sysmac automation platform. The Machine Automation Controller integrates logic, motion, safety, robotics, vision, information, visualization and networking under one software: Sysmac Studio. This one software provides a true Integrated Development Environment (IDE) that also includes a custom 3D motion simulation tool. The machine controller comes standard with built-in EtherCAT and EtherNet/IP. The two networks with one connection purpose and integrated safety are the perfect match between fast real time machine control and data plant management.

EtherCAT – Machine Control

• Redundancy minimizes downtime

• Flexible system configuration using a variety of slaves

• Fast and precise: Fastest cycle time of 125 μs, synchronization with 1 μs jitter

• 512 slaves

• Embedded in Omron servo drive, inverter, I/O, Safety, Vision and Sensing

• Uses standard STP Ethernet cable with RJ45 connectors

• One connection using Safety over EtherCAT (FSoE) protocol

Ethernet – Factory Automation

• Peer-to-Peer controller communication

• Interface with Sysmac Studio , NA HMI or SCADA software

• Database connection for Microsoft SQL Server, Oracle, IBM DB2, MySQL and Firebird

• FTP server

• Safety integrated via CIP Safety

• Secure cloud connection by MQTTS communication

- One Integrated Development Environment Software

- Created to give you complete control over your automation system, Sysmac Studio integrates configuration, programming and monitoring. Graphicsoriented configuration allows quick set-up of the controller, field devices and networks while machine, motion, and safety programming based on IEC standard and PLCopen® Function Blocks for Motion Control and Safety cuts programming time. Smart Editor with On-line debugging helps quick and error free programming. Advanced simulation of sequence and motion control, and data trace reduce machine tuning and set-up.

- Powerful, yet easy to configure

- The NJ/NX/NY Controller is at the heart of the Sysmac platform. One integrated controller is designed to meet extreme requirements in terms of logic sequence and motion control speed and accuracy. Standard programming and open networks make it easy to build your automation system.

- High-speed, high-precision control *1

- Architecture based on Intel® CoreTM processor significantly speeds up the execution of instructions (basic instructions 0.37 ns, math instructions for Long Real Data 3.2 ns). Command values to send to servomotors and stepper motors can be updated as fast as every 125 μs.

This enables smooth cam motion and high-precision interpolation and phase adjustment between axes. - Complete integration of motion and logic

- One controller integrates logic, motion, vision and information for complete control and management of machines. Position, displacement, and tension information collected from sensors can be quickly and easily fed back to the motion control.

- Integrated safety into machine control*3

- The controller integrates safety control into machine control in lines that require fast cycle times. It also integrates two different open networks: EtherNet/IP for safety control in production lines and EtherCAT for safety control in machines.

- Cable Redundancy

- Even if a part of the EtherCAT network is disconnected, Cable Redundancy provides continuous connectivity. This function allows you to fix disconnection without stopping the machines and production line where one controller provides both machine and safety control.

The line stops only when operators are in danger, which ensures safety.

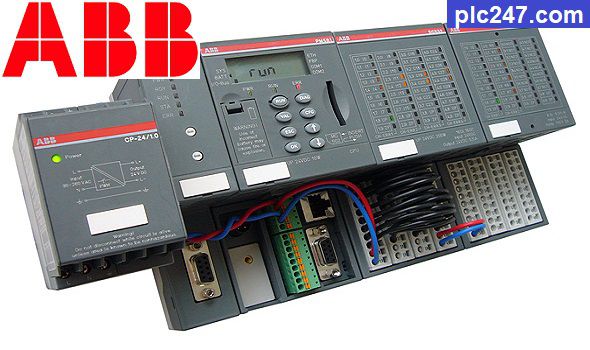

6- ABB (B&R automation)

- The AC500, AC500-eCo, AC500-S and AC500-XC scalable PLC ranges provide solutions for small, medium and high-end applications. Our AC500 PLC platform offers different performance levels and is the ideal choice for high availability, extreme environments, condition monitoring, motion control or safety solutions.

Our AC500 PLC platform offers interoperability and compatibility in hardware and software from compact PLCs up to high end and safety PLCs.

AC500

Our powerful PLC featuring a wide range of performance, communications and I/O capabilities for industrial applications. The ideal choice for complex, high speed machinery and networking solutions. - AC500-eCo

This compact PLC is offering optimally suited flexible and economical configurations for automation solutions in smaller applications.

AC500-S

This safety PLC (SIL3, PL e) is designed for safety applications involved in factory, machinery or process automation area. The ideal choice to implement and manage complex safety solutions. - AC500-XC

Extreme Condition PLC variant of the AC500 platform with extended operating temperature, immunity to vibration and hazardous gases, use at high altitudes and in humid environments.

The software :

- ABB Automation Builder is the integrated software suite for machine builders and system integrators wanting to automate their machines and systems in a productive way. Combining the tools required for configuring, programming, debugging and maintaining automation projects, Automation Builder addresses the largest single cost element of most of today’s industrial automation projects: time spent on working with software.

- ABB Automation Builder covers the engineering of AC500 PLCs, AC500 safety PLCs, CP600 control panels, drives and motion.

- Automation Builder is available for download from this website. A convenient setup helps to configure the installation. It also handles license registration, maintenance and updates of the software.

- Automation Builder is available in Basic (free), Standard and Premium editions fitting the needs of small projects and managing the challenges of many and large projects for OEMs and system integrators.

- Automation Builder is immediately available by using the incorporated 30-day test license.

- To learn more, please see Automation Builder Platform and Software pages.

- ABB Automation Builder is the integrated software suite for machine builders and system integrators wanting to automate their machines and systems in a productive way. Combining the tools required for configuring, programming, debugging and maintaining automation projects, Automation Builder addresses the largest single cost element of most of today’s industrial automation projects: time spent on working with software.

- ABB Automation Builder covers the engineering of AC500 PLCs, AC500 safety PLCs, CP600 control panels, drives and motion.

- Automation Builder is available for download from this website. A convenient setup helps to configure the installation. It also handles license registration, maintenance and updates of the software.

- Automation Builder is available in Basic (free), Standard and Premium editions fitting the needs of small projects and managing the challenges of many and large projects for OEMs and system integrators.

- Automation Builder is immediately available by using the incorporated 30-day test license.

- To learn more, please see Automation Builder Platform and Software pages.

- AC500 Engineering is fully integrated into Automation Builder and covers the configuration, programming, debugging and diagnosis for ABB’s AC500 PLCs and AC500 safety PLCs.

- AC500 Engineering covers all IEC 61131-3 programming languages and delivers additional productivity features such as

- integration with ABB Drives and CP600 control panels

- object-oriented programming of AC500 V3 CPUs

- project comparison

- interfaces for data exchange with external tools

- programming in C++

- scripting for automating configuration and programming tasks

- flexible configuration allowing to use one PLC application with various hardware configurations

- wide range of debugging, simulation and online diagnosis features.

- Various AC500 libraries are available to facilitate and speed up your programming tasks – reaching from communication via motion control to application-specific libraries. To learn more, please see the AC500 libraries offering.

For AC500 there is an increasing number of features available that can be used by obtaining additional licenses, e.g. further communication protocols. To learn more, please see the AC500 license features site.

In addition, a rich set of application examples helps you to quickly solve almost any automation challenge.

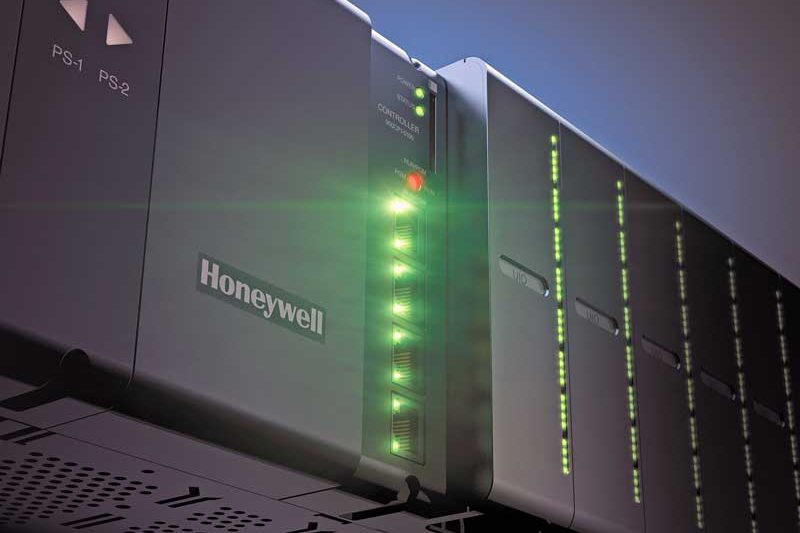

7-Emerson Electric (GE) –RX3i & Versamax

Your operations need an agile, efficient approach to plant modernization. Emerson’s PACSystemsTM industrial automation and controls solutions adds a new dimension to the industrial control and automation landscape, allowing optimized production, better connectivity, and precise control capabilities in a wide range of process and discrete industrial environments. Most important, PACSystems enables flexible, adaptable upgrades and expansions as your needs change and priorities shift. No matter how fast your operation is growing or diversifying, PACSystems brings control intelligence with a real-world approach closer to the industrial edge.

- Patented heat-transfer features and built-in redundancy help ensure high availabilitycontrol in even the toughest operating conditions while minimizing the potential for mechanical failure.

- Mitigate threats and protect against intrusions with a complete defense-in-depth strategy. Advanced security features verify the integrity of vital system components and help prevent unauthorized controller access.

- Communicate seamlessly with plant floor devices and supervisory systems to drive performance and optimize productivity using standard communication protocols for maximum interoperability and ease of use.

- Monitor, manage and adjust production on-the-fly using powerful edge technology. Manage critical assets and enable fast, informed actions with insights close to the source.

- In automation controls applications across all industries, ranging from process to discrete, expansion and diversification are driving the need for flexible, scalable control solutions. PACSystems solutions allow end users and OEMs to bring their operations into the modern world at a realistic and affordable pace, scaling and upgrading to meet the needs of today’s buying trends and production realities. With connectivity at its core, the PACSystems devices and architecture reaches beyond conventional standards to anticipate trends and re-imagine the intersection of control, software, interfaces and devices to meet your future industrial automation and control needs.

- Drive productivity and speed development with secure, collaborative and integrated control software. Program and configure PACSystems devices using native tools, open standards, and a fully integrated development environment. Apply version control and authenticate and secure communications using a common set of configuration tools.

- Tackle a diverse range of application requirements with the robust, reliable line of PACSystems industrial controllers. Delivering deterministic, high-speed control (from as low as 24 to over 32,000 I/O points), these best-in-class controllers are interoperable with most industry standards, redundant and secure by design, and operate without compromise in the most demanding conditions.

- Give your operators fast, clear access to data with the PACSystems line of rugged industrial displays. The comprehensive portfolio of modular HMIs and touchscreen devices combines the ease of use of consumer-grade technology with the industrial-level durability needed for harsh environments. The modular design allows for easy scalability while built-in daisy chaining capability helps simplify connectivity and reduce costs.

- In automation controls applications across all industries, ranging from process to discrete, expansion and diversification are driving the need for flexible, scalable control solutions. PACSystems solutions allow end users and OEMs to bring their operations into the modern world at a realistic and affordable pace, scaling and upgrading to meet the needs of today’s buying trends and production realities. With connectivity at its core, the PACSystems devices and architecture reaches beyond conventional standards to anticipate trends and re-imagine the intersection of control, software, interfaces and devices to meet your future industrial automation and control needs.

- Drive productivity and speed development with secure, collaborative and integrated control software. Program and configure PACSystems devices using native tools, open standards, and a fully integrated development environment. Apply version control and authenticate and secure communications using a common set of configuration tools.

- Tackle a diverse range of application requirements with the robust, reliable line of PACSystems industrial controllers. Delivering deterministic, high-speed control (from as low as 24 to over 32,000 I/O points), these best-in-class controllers are interoperable with most industry standards, redundant and secure by design, and operate without compromise in the most demanding conditions.

- Give your operators fast, clear access to data with the PACSystems line of rugged industrial displays. The comprehensive portfolio of modular HMIs and touchscreen devices combines the ease of use of consumer-grade technology with the industrial-level durability needed for harsh environments. The modular design allows for easy scalability while built-in daisy chaining capability helps simplify connectivity and reduce costs.

- Reap the benefits of best-in-class connectivity and continuous uptime with PACSystems PROFINET-based devices and I/O portfolio. Mix and match a variety of industrial I/O as well as other industrial devices to meet your unique application demands. The right I/O for the right job reduces component cost and installation time and optimizes ROI.

- Today’s industrial enterprises face increased security threats that can cause long-term damage. You need a dynamic, cohesive security strategy that is always evolving and is built into all layers, from the hardware and software to communications and the development process. PACSystems solutions are designed with extensive, multi-level security. It is secure by design so you can verify and validate the integrity of vital system components. It incorporates defense-in-depth to mitigate attacks and protect at every layer through robust end-to-end security. Secure communications helps prevent attackers from gaining unauthorized access to the controller.

- Whether it’s a small machine or a complete plant, PACSystems controllers let you choose the size of your controller and the optimal programming environment, while delivering speed, reliability and an unmatched level of security. With integrated control capabilities that can connect devices and machine-level data across all areas, PACSystems controllers help deliver high productivity and dependable performance in any environment.

- Offering a base scan rate as low as 200 μS, switchover as fast as 1 scan, high-speed coordinated multi-axis motion, and fully deterministic control, PACSystems meets the needs of today’s applications.

- PACSystems provides the widest range of communications options for maximum interoperability – DNP3, IEC 61850, IEC 104, HART pass-through, EGD, SRTP, Modbus-TCP/RTU, PROFINET, OPC UA.

- Built on a scalable, synchronized, redundancy control platform, high availability solutions provide uninterrupted control of your applications and processes.

- PACSystems controllers are Achilles-certified and come with the latest security constructs, such as Secure Boot, TPM and secure f irmware upgrades.

- Profinet protocol

- Hot swapping of I/O modules enables service activities to be performed while the system is still active.

- PACMotion servo solutions provide users and OEMs with an integrated development, control, motion visualization and safety solution, all designed for efficiency, simplicity and rapid ROI. PACMotion combines an integrated motion and machine logic solution with the performance, flexibility and scalability required for advanced machine automation. Configured to provide the easiest integration and development, greatest precision and yield, and reduced maintenance, the PACMotion controller, servo drives and servo motors are designed to work together in applications from a few to up to 40 axes without performance degradation.

- The unique design of the PACMotion controller backplane allows higher speeds than traditional networks. EtherCAT communications is updated every 250 μS, the position loop updated every 500 μS, and the path planner loop updated every 1 ms.

8- Hitachi PLC

Recognized as a global leader in developing PLC controller and industrial control systems, Hitachi Industrial Equipment and Solutions America has been consistently providing advanced PLC systems and PLC control systems.

- Modular series:

- EHV

- Compatible with a variety of open networks, the EHV series can be linked to other PLC systems through the use of the onboard Ethernet interface.

- EHV+Series

- Explore our EHV+ series which includes one of the first general PLCs in the world based on the CoDeSys V3 runtime system.

- MICRO-EHV+ Series

- Powerful communication performance in one CPU

All models have Ethernet, serial, USB (host & device) communication ports as standard.

Additional communication ports can be realized by option boards.

- Compact series:

- Micro-EH Series PLC

- The Micro-EH Series PLC is a compact PLC with 12 bit analog I/O, built-in high speed counter, PWM and pulse train output with maximum 140 I/O points.

- The EHV+ Series is a fully IEC61131-3 compliant PLC Series which offers effective programming features and reduced debugging and commissioning time.

- The powerful hardware performances of existing EHV Series are succeeded to EHV+, such as multi-programming port (USB, Ethernet, Serial), compatibility of I/O modules for EH-150 Series, high reliability, superior in quality and much more.

- Integrated Development Environment (IDE) “HX-CODESYS“

- HX-CODESYS is a professional development tool based on CODESYS V3.5 by 3S.

Compared to standard CODESYS, following components are additionally included in the installation file(setup.exe) - – Device description files (.xml) for EHV+ Series

– Special libraries for EHV+ Series. (get_error_info, Counter_interface, etc.) - ■ Standardized programming style with 5 programming languages (LD, FBD, IL, ST, SFC).

- ■ No need to study manufacturer’ s specific programming way.

- ■ Easy to start using Hitachi PLC for those who having;

No experience of PLC

Experience of other manufacturer’s programming

Experience of high level languages - ■ Same Variable names are shared by PLC, HMI, SCADA, and other I/O devices.

- ■ Offline simulation function on programming software.

The Software:

- CODESYS – globally accepted, standardized programming software � Easy to use for PLC beginners, computer system engineers etc. � Variable names can be commonly used between PLC, HMI and SCADA

- Depending on its connection combination, various topologies are possible Ethernet- EtherCat- OPC-UA

- Trajectory control by G code. Possible to read out coordinates from DXF files. Examples: X-Y table, Multiple joint robots, Tripod robots

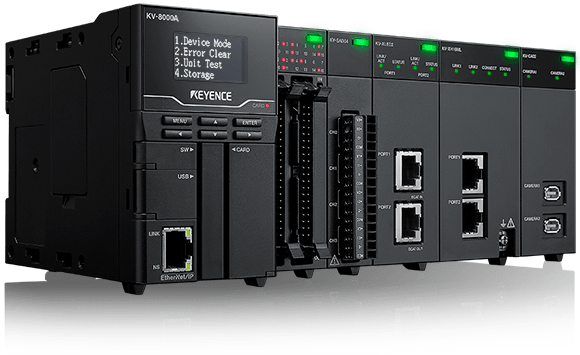

9- Keyenc – PLC

- KV nano series:

- The KV Nano not only uses the same software as other KV PLCs, but it also dispels the notion that programming methods cannot be consistent across different PLC models. You can still use functions like KV Script and real-time chart monitor, regardless of the PLC model.

- The expansion unit of the KV Nano Series can not only be used for remote I/O but also works as a shared remote I/O with the KV-8000 Series. This allows you to use the same parts for large and small applications, resulting in cost reduction.

- By using the connection conversion unit, you can connect terminal block type expansion units. This allows you to select the optimum units when designing the system.

- The KV-EP02 supports both line- and star-type connections. Since there are 2 ports, the unused port can be used as a switching hub to allow flexible wiring

- 24 VDC power can be supplied directly from a control panel to the CPU unit, eliminating cost for a power supply unit.

- You can monitor various items simultaneously on one screen, including the current coordinates, speed, and a positioning complete flag. When the real-time chart monitor is opened from the built-in function monitor, related devices are registered automatically

- Various operations from positioning control to synchronous control can be performed with a single unit. Interpolation control and synchronous control can be achieved in much the same way as performing positioning. The automatic ladder creation function also helps reduce design time.

- All channels support high-speed pulse inputs of 100 kHz (phase difference: 50 kHz). The 32-bit resolution ensures highly precise control similar to modular-type PLCs.

- The high-speed counter enables the use of various functions without being affected by scan time, resulting in high-speed processing equivalent to modular-type PLCs.

- A rotary encoder can be connected to provide an output at a specified position (angle). Up to 32 points of output positions can be set in units of 0.1 degrees. Both absolute and incremental encoders are supported.

- The KV Nano is compatible with KV STUDIO, the configuration software for the KV Series.

- Calculation processing programs can be executed just by writing the formula directly. This not only reduces programming hours but also increases visibility when debugging.

- Unlike with ladder programming, syntaxes and various functions required for advanced processing can be described concisely.

- In accordance with the highspeed performance of the CPU unit, the conversion speed has been increased greatly to 10 µs/channel. The resolution has also been improved to 1/20000 to ensure high precision. This leads to higher production efficiency and improved quality

- Equipment data is recorded in chronological order whenever a problem occurs. This enables you to see exactly what happened both before and after the event

- Record all devices changes based on scan time resolution. The ability to display data together with the ladder program makes analysis easy

- Records the event log from the HMI, PC, or PLC. This enables to you to see in chronological order what change both before and after the problem occurred.

- Record equipment operation by using the camera unit. Recording is synced to the ladder program, which allows for easy analysis later.

- In addition to recording data before and after a problem occurs, it’s also possible to record at the start of normal equipment cycles. Using this normal cycle data as a reference aids in analysis when a stoppage without an alarm occurs.

- The only setting that needs to be configured for equipment problems is the trigger. In addition, up to 4 operation settings can be registered, which enables customizable recording settings for different faults.

- Synchronized playback

- Recorded data can be played back later in replay mode. The playback bar can be used to go back in time to before when the problem occurred.

- The ladder program, waveform data, camera image, and event/error log are synchronized during playback to accurately understand the conditions both before and after the problem occurred

- Data recorded by the Machine Operation Recorder function can be imported and played back using the onsite touch panel (VT5-WX). The ability to check statuses on-site without a PC makes understanding the situation easy and quick.

- Preset system screens are available for monitoring camera video, user operation history, waveforms, and ladder programs. Start using quickly without needing to create screens

- Keyenc – PLC

- Analysis function

- Search/extract not only device and configuration changes related to the error but also externally rewritten devices, and create a tree diagram automatically. Causes can be investigated quickly just by following the block.

- Automatically extract related ladder programs by selecting a block within the relation map. Narrow down and check only the code that caused the device to change, ensuring more efficient cause analysis.

- Search for the moment when a device changed. This enables confirmation when a bit goes high or a word reaches a specific value. Because the current playback position can be changed due to the search, analysis can be performed with greater efficiency

- Normal and abnormal waveforms can be superimposed for comparison in the event of an error. Cycle waveforms can also be automatically overlapped from the cycle’s start signal to identify the cause of problems as quickly as possible.

- Keyenc – PLC

Keyence is a Japanese Company

Pros:

Excellent for troubleshooting – with the features such as video recording user can easily identify the problem and tackle the challenge.

Excellent web server service. Makes it easy to monitor all the machine in different location

user friendly software in comparison with other Japanese PLC brands

Cons:

More suitable for machine building rather than big plants or factories

Very strict access to document such as learning tutorials

No free trial or access to the software

10- Phonics contact

PLCnext Technology is the ecosystem for industrial automation consisting of open hardware, modular engineering software, a global community, and a digital software marketplace. Digitalization and globalization are placing new demands on industrial automation. The precisely-tailored design of the open automation system is just as important as flexible, modular expansion.

In addition to standard PLC programming in accordance with IEC 61131-3, parallel programming and the combination of programming languages such as C/C++, C#, and MATLAB® Simulink® in real time is also possible with PLCnext Control. Accelerate your application development process with the free basic version of PLCnext Engineer. Or use your familiar programming environment – you decide!

Through simple cloud integration, the option to use open source software, and the constantly growing expertise of the PLCnext Community, you thus benefit from new forms of collaboration. The resulting solutions apps, software modules, runtime systems, and function extensions are available in the PLCnext Store and ensure enormous time and cost savings when creating applications. This makes PLCnext Technology the ideal ecosystem for your modern automation challenge.

Use our broad portfolio of automation technology consisting of PLCs, functional PLC extensions, I/O systems, and software to ready your system for IIoT and Industry 4.0 with PLCnext Technology. The open ecosystem enables the implementation of automation projects without the limits of proprietary systems. Integrate open-source code and apps, or network with PLCnext Control via cloud connections.

PLCnext Technology allows parallel programming based on established software tools. These include Visual Studio, Eclipse, Matlab Simulink, and PLCnext Engineer, as well as the freely selectable integration of existing program code. This enables you, for example, to freely combine functions in accordance with IEC 61131-3 with routines from C/C++, C# or MATLAB® Simulink®, and to merge these functions to create a complete system.

Phoenix Contact provides scalable PLCs with the IP20 degree of protection for this purpose. From modular controllers for small applications, through centrally managed high-performance controllers, right through to PC-based edge devices, this product family always provides a suitable solution for your project. The modular controllers give you a high degree of flexibility in the design of your stations. Choose from a wide portfolio of I/Os or extend the functionality of the controller by adding function modules on the left side. You can also integrate new technologies such as OPC UA, TSN, and 5G with the open Linux core. PLCnext Control thus offers the highest level of future-proofing.

Phoenix Contact provides a broad PLC range for any requirement. Choose from programmable logic controller technology with the appropriate I/Os and high-performance PLCs for demanding automation tasks for small to medium-sized systems.

The modular controllers from the Axiocontrol series are designed for maximum performance, easy handling, and use in harsh industrial environments. Their particularly robust housing and excellent EMC properties provide the basis for this.

For high-availability and decentral automation, the high-performance PLC with

IEC 61131 control intelligence, redundancy technology, and network connection is the

ideal solution. The integrated fiber optics-based redundancy function enables an

uninterrupted process in the event of a PLC failure or replacement. RFC controllers are based on PROFINET and establish system redundancy automatically thanks to AutoSync Technology.

Engineering software platform for Phoenix Contact automation controllers. PLCnext Engineer is IEC 61131-3-compliant and is available free of charge under Downloads. Its functionality can be extended using paid add-ins. To do this, open the license configurator via the “Configure” button.

Pros:

High flexibility to use programming language platform including C++/C# Python, Matlab and Simulink plus standard programming language of IEC 61131-3

Free Software + paid add-ins

Good range of Products

Reasonable price

Cons:

Not suitable for large plant and factories automation

Not easily accessible on the market to order (Long waiting time)

Price:

11- Delta PLC

Hot Swappable Mid-range PLC – AH Series

AH Series PLC provides automation solutions for high-level applications. The combination of modularized hardware structure, advanced functions, and the highly integrated software provides a system solution for process control applications. In addition to various function blocks (FB), excellent price/performance, and an abundant selection of extension modules, AH Series PLC also provides multi-axis motion control via motion network, such as EtherCAT, to perform high-speed, high-precision machine control. The exceptional system expandability also greatly reduces the system cost for a broad range of applications.

Compact Modular Mid-range PLC – AS Series

The Delta Compact Modular Mid-range PLC AS Series is a high performance multi-purpose controller designed for all kinds of automated equipment. AS series standard CPU features Delta’s self-developed 32-bit SoC CPUs for enhanced execution speed (40 k steps/ms) and supports up to 32 extension modules or up to 1,024 inputs/outputs. It provides accurate positioning control for up to 8 axes via CANopen motion network and max. 6 axes via pulse control (200 kHz). AS series motion CPU features EtherCAT/CANopen motion control interface and multiple communication ports. It also offers motion control function blocks complying with international standards and synchronizes up to 16/24 real axes in one update cycle. AS series controllers are widely used in diverse automated equipment such as packaging, printing, labeling, textile and pharmaceutical industries.

Programmable Logic Controllers – DVP Series

Delta’s DVP series programmable logic controllers offer high-speed, stable and highly reliable applications in all kinds of industrial automation machines. In addition to fast logic operation, bountiful instructions and multiple function cards, the cost-effective DVP-PLC also supports various communication protocols, connecting Delta’s AC motor drive, servo, human machine interface and temperature controller through the industrial network in to a complete “Delta Solution” for all users.

ISPSoft Programming Software

ISPSoft is a highly accessible programming software application for Delta’s programmable logic controllers (PLC). With its modular editing interface, ISPSoft integrates hardware configuration, network configuration, and motion control programming into the same editing platform. The user-friendly ISPSoft provides graphical interfaces and convenient wizards to enhance software accessibility as well as editing flexibility. ISPSoft offers up to 5 programming tools*, including: Ladder Diagram (LD), Function Block Diagram (FBD), Sequential Function Chart (SFC), Instruction List (IL), and Structured Text (ST), allowing users to choose proficient tools for better editing efficiency. Delta’s ISPSoft adopts the IEC 61131-3 standard and supports PLCopen® function blocks for quick configuration of motion control programs that helps you save on project development time and achieve more intelligent and powerful industrial control solutions.

Pros:

Its cheap comparing to the other brands

The software is free!

It has good range of product from small to mid size application

Delivery is Fast

The learning material is available and good

Cons:

Not high quality like other brands

Personal experience: There was many bugs in the software. hopefully was resolved by updated versions

Not suitable for plant or factory automation

I Hope you like this list!

Nima Rashvand

Donation!

Please support me to write interesting articles about Industrial Machinery and Automation. Thanks 🙂

€5.00

Leave a comment