In this Episode, i have explaind that the Spot welding is based on the high current that passes through different resistive material to create extream heat at a tiny point. The thinnes of the metal sheets is usually between 0.5 to 3 mm and the amount of the current and clamping force of the welding gun is based on the type of the material and requires proper transormers. The clamping force makes the welding point under stress to be squeezed and let the welding Joint have a stronger attachment and a better quality.

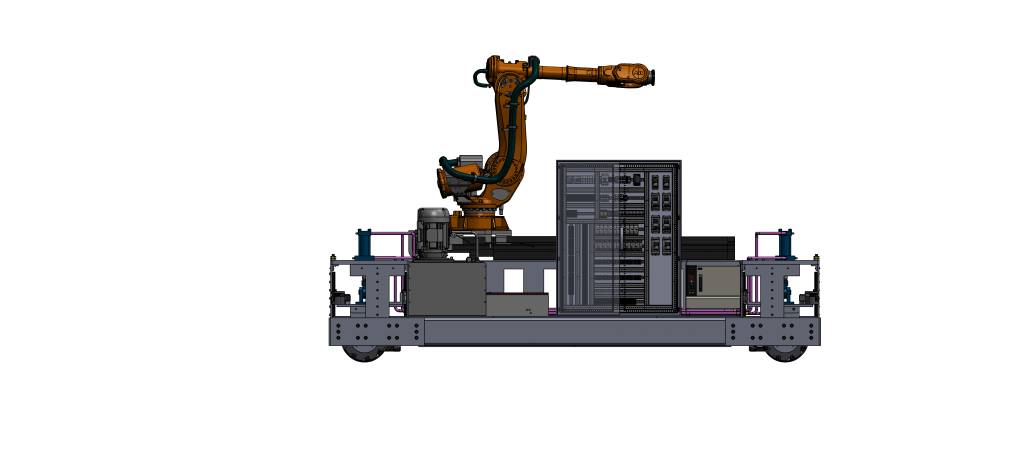

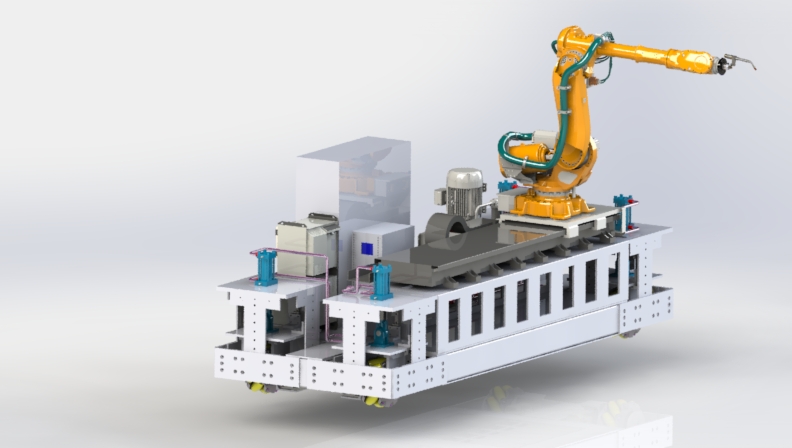

In this Episode, I have used TX-86 the recharchable hydraulic mobile platform that can lift up 1000 kg weight and move manually to the required position. The electrical cabinet includes the 8 Motor inverter that four of them belongs to the inductive motors with 2.2 KW power on each wheel. The other four Inverters can be connected by cable to the external conveyors that transfer the material for robot tasks.

TX-86 hydraulic mobile robotic platform

I did simulate the spot welding in ABB Robot Studio software which is the main platform to program and simulate ABB robots. Below you can find and download the Rapid code dedicated to simulate the spot-welding application:

Donation

If you Like my Work and blog, please support me to create and design more Intresting machinery! Thank you 🙂

€5.00

Leave a comment